India generates over 230 million tonnes of surplus biomass every year — much of it burnt, wasted, or unmanaged. We're using this opportunity to create something powerful: clean energy, circular value chains, and climate resilience.

Crafted from India’s agricultural surplus — paddy straw, bagasse, cotton stalks, pine needles, and more — our pellets deliver consistent heat and cleaner combustion for everything from thermal power plants to industrial boilers.

India burns almost 1 billion tonnes of coal per year. Pellet co-firing could displace 50 million tonnes annually. By using Zero Pellets, thermal plants and factories can:

Stubble burning is choking the air — and the economy. Our model

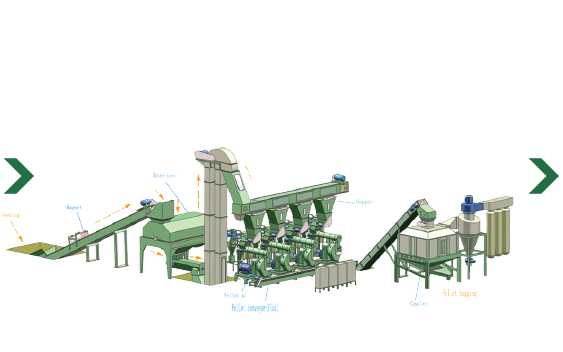

Each 2TPH plant can create ~70 sustainable rural jobs, directly and indirectly. Through our FPO and cooperative partnerships, we:

Pellets offer: